Biogas Desulfurization De

Our GasCle system is for the pre-treatment of raw biogas from anaerobic reactor, suitable for biogas flow 20 ~ 300 Nm³/h

Send your inquiryDESCRIPTION

Basic Info.

| Desulfurizer Agent | Ferric Oxide |

| Transport Package | Wooden Case |

| Specification | 3000*2000*2200 mm |

| Trademark | ALONG BIOGAS - ALBS |

| Origin | China |

| HS Code | 8486909000 |

| Production Capacity | 1000 Sets/Year |

Product Description

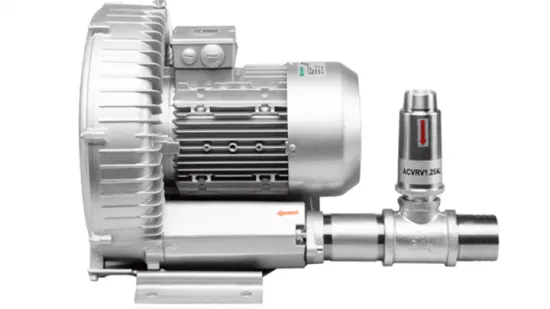

Our GasCle system is for the pre-treatment of raw biogas from anaerobic reactor, suitable for biogas flow 20 ~ 300 Nm³/hr. The raw biogas from digester always contains saturated water vapor, physical impurities and hydrogen sulfide. These substances should be removed before the utilization of biogas, to avoid damage to generator, burner of boiler and torch or other equipment.The GasCle system is skid mounted in combination of multiple functional units, or individually installed at project site.GasCle system has the following modules:1. Primary filter (optional)For preliminary removal of physical impurities and saturated water vapor;2. Desulphurization tank.For reducing the hydrogen sulfide content in biogas, to meet the requirements of follow-up equipment;3. Secondary filter.For Precise removal of physical impurities in the biogas and moisture;4. Biogas blowerIncreasing biogas pressure for transportation and meed the requirement of follow-up equipment for gas intake pressure;5. Electrical control systemEquipped with VFD(variable frequency drive) and LCD touch screen.- Pressure gauge and H2S analyzer(Optional).- Pipes, valves and base frame.GasCle system has the following functions:1. DesulfurizationHydrogen sulfide can be reduced to 50ppm or less;2. DehydrationRemoval of saturated water vapor;3. Impurity removal.Removal of physical impurities and volatile matter of desulphurizer agent;4. Pressure increasingIncrement could reach 39.8 kPa or even higher;5. Pressure stabilizationStabilizing gas outlet pressure at a fixed value to meet the gas intake pressure requirement of the follow-up equipment;6. Measurement of Pressure and hydrogen sulfide content (optional);7. Digital display.Pressure setpoint, gas outlet pressure, motor frequency, motor speed, motor current, output torque, bus voltage, output voltage, power consumption and system operation time would be indicated on the LCD display.